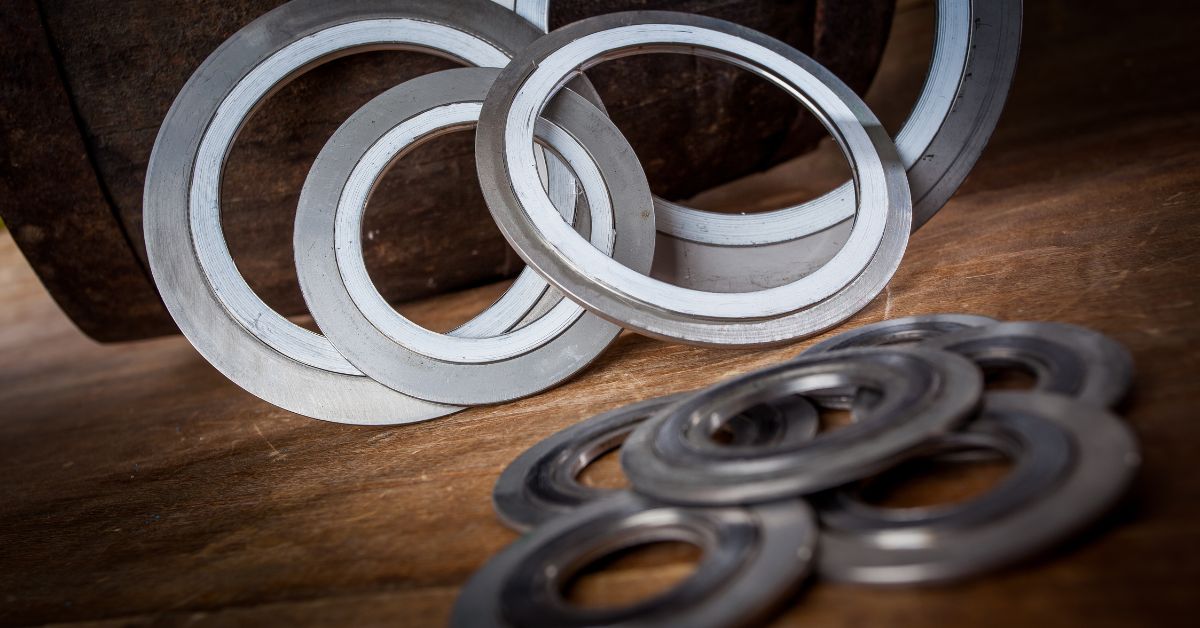

Tank manway gaskets may seem like a small component, but their role in maintaining tank integrity is critical. These essential components create airtight seals that prevent leaks, safeguard hazardous materials, and protect against environmental damage.

Selecting the right gasket requires a precise understanding of the guidelines set by the American Society of Mechanical Engineers (ASME). We’ll provide a guide on ASME standards for tank manway gasket selection to help you ensure safety and compliance.

Understanding ASME Standards

The American Society of Mechanical Engineers (ASME) develops codes and standards designed to ensure the safety, quality, and reliability of engineering systems, including tank manway gaskets. These protocols provide detailed instructions for materials, dimensions, and design, offering consistency across industries and applications.

Key ASME Sections for Manway Gaskets

ASME Section VIII, Division 1

Division 1 outlines the general requirements for the design, fabrication, and inspection of pressure vessels, including manway closures and associated gaskets. Section UG-11 is particularly significant, focusing on closures and seal components used under various pressure and temperature ranges.

ASME Section VIII, Division 2

This section covers alternative and more performance-based rules for pressure vessel design. It’s suitable for more demanding applications, providing additional flexibility in gasket and manway fabrication without compromising safety.

ASME standards ensure that manway gaskets meet performance and safety requirements, making them a non-negotiable component in transport and storage systems.

Material Selection for Tank Manway Gaskets

Choosing the right material for your gasket depends on your tank’s operating conditions and specific applications. Below are some common materials that meet ASME standards:

- Buna-N: Buna-N gaskets are widely recognized for their excellent resistance to oils and fuels, making them a reliable choice for demanding environments. This durability and performance make them particularly well-suited for petroleum-related applications.

- Viton: These gaskets provide exceptional resistance to heat, chemicals, and solvents, ensuring durability and reliability in extreme conditions. This makes them an ideal choice for use in heavy-duty machinery and chemical transport systems where performance is critical.

- Silicone: Silicone materials are known for their ability to remain effective under extreme temperature variations, making them highly versatile. They perform reliably in high-heat conditions and freezing environments, ensuring consistent functionality across various applications.

- EPDM: These gaskets are highly effective in applications involving water-based solutions, offering reliable performance in even the most challenging environments. They are designed to resist UV light and weather exposure, ensuring long-lasting durability and efficiency.

- Teflon-encapsulated options: Equipped with a Teflon coating, these gaskets provide superior chemical resistance, ensuring durability and reliability. This makes them an ideal choice for handling highly corrosive substances with ease and efficiency.

Factors Influencing Selection

Choosing the right tank manway gasket material is critical to ensuring optimal performance and safety. Several key factors must be considered to ensure the gasket effectively meets operational demands and environmental conditions.

- Chemical compatibility: Ensure the material is chemically resistant to the tank’s contents.

- Temperature resistance: Choose gaskets that can withstand the temperature range of the application.

- Pressure requirements: Ensure the gasket can endure the operational pressure without failure.

By selecting the optimal gasket material, you enhance performance and reduce maintenance costs.

Guidelines for Gasket Sizing and Dimensions

Proper sizing is paramount to ensuring an airtight seal. Here are fundamental ASME guidelines for gasket sizing:

Sizing Parameters

- Inner diameter (ID): The gasket’s inner diameter should align perfectly with the flange’s inner diameter.

- Manway opening size: Consider the dimensions of the manway opening when selecting the gasket.

Gaskets for Custom and Non-Standard Sizes

Not all tanks conform to standard dimensions. If your tank features custom designs, ensure detailed measurements are supplied to the gasket manufacturer for precise sizing.

Small inconsistencies in sizing can result in inadequate sealing, leading to potential leaks or system failures.

Design and Construction Guidelines

ASME guidelines emphasize reliability in the design and construction phase of tank manway gaskets. Critical design considerations include:

- Profiles: Select gasket profiles that can endure variations in pressure and temperature. Popular profiles include flat gaskets, O-rings, and special cross-sections.

- Material resilience: Use materials that can maintain elasticity under stress, ensuring a long-term seal.

Recommendations for Reliable Seals

- Ensure a smooth surface finish for flanges to achieve a tighter seal.

- Choose gaskets designed to prevent creep (deformation over time).

Construction aligned with ASME standards ensures durability and performance, safeguarding the integrity of your tank.

Testing and Certification for Gasket Performance

ASME Testing Requirements

ASME standards stipulate rigorous testing to guarantee that gaskets meet performance criteria under various conditions. Testing may include:

- Pressure tests to confirm the gasket’s ability to sustain operational loads.

- Chemical resistance tests to determine compatibility with tank contents.

- Temperature endurance tests to validate performance under extreme temperature conditions.

Certification Protocols

Manway assemblies that are certified and stamped in compliance with ASME codes indicate they meet the highest safety and quality standards. Certification also reduces liability risks, providing peace of mind that the equipment is built to meet regulatory standards.

Steps To Ensure Compliance and Safety

Maintaining compliance and safety for tank manway gaskets requires adherence to established standards and careful attention to operational details. Implementing the right procedures ensures durability, performance, and alignment with safety regulations.

Select ASME-Compliant Components

Thoroughly review the materials, size, and design of your gaskets to meet ASME criteria. Verifying compliance with these standards is essential for reliability and safety in your applications.

Partner With Reputable Suppliers

You can rely on established suppliers like Girard Equipment for high-quality, ASME-compliant tank manway gaskets. Our products are trusted across the industry for their durability and reliable performance.

Regular Inspections and Maintenance:

Regularly perform thorough checks to ensure gaskets and closures are in optimal condition. This helps prevent potential issues and ensures long-term reliability.

Why Choose Girard Equipment?

At Girard Equipment, our manway gaskets are designed with precision and durability in mind. We offer various ASME-compliant gaskets and closures, delivering reliable solutions for tanker operators and fleet managers. Every product we supply is built using cutting-edge technology, ensuring it surpasses quality expectations.

Choose the Best for Your Tanks

Ensuring tank integrity begins with selecting the right gaskets. Understanding the ASME standards for tank manway gasket selection is essential to prevent leaks, optimize operations, and maintain safety. Each aspect plays a critical role in gasket performance, from material selection to sizing and certification.

Trust in experts like Girard Equipment to provide the solutions your operation needs. Check out our tanker dome lid gaskets today and secure peace of mind for your fleet.