Transporting hazardous chemicals presents a unique set of challenges, chief among them the safe handling of potentially dangerous vapors. For operators of DOT407 tank trailers, vapor recovery systems are an essential solution that enhances safety, improves environmental stewardship, and ensures regulatory compliance.

This guide offers a comprehensive understanding of vapor recovery on DOT407 tank trailers, detailing their components, benefits, and maintenance requirements. Whether you’re a tanker operator, fleet manager, or involved in the transport industry, this guide will provide the insights you need to operate more efficiently and safely.

What Is Vapor Recovery?

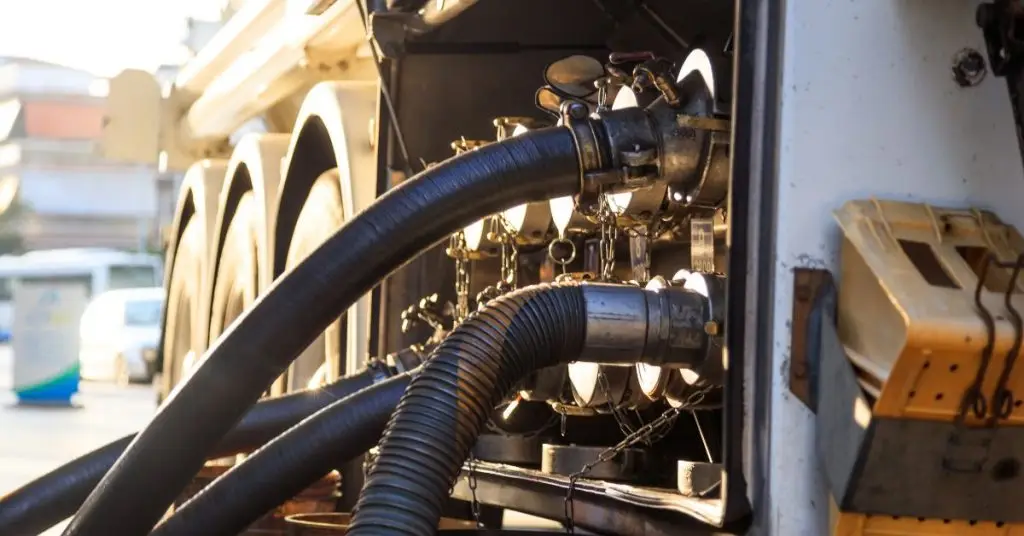

Vapor recovery refers to the process of capturing vapors generated during the loading, unloading, and transportation of chemicals that volatilize at ambient or elevated temperatures. These vapors, which often contain harmful compounds, must be prevented from escaping into the atmosphere.

A vapor recovery system accomplishes this by using a network of components that collect and redirect vapors into containment or back to the source facility for reuse. This system enhances operational safety while adhering to environmental and industry standards.

Components of a Vapor Recovery System

A vapor recovery system on a DOT407 tank trailer is designed to safely manage and control the release of hazardous vapors during the transportation of chemicals. These systems comprise specialized components engineered to capture, contain, and redirect vapors, thereby minimizing environmental impact and ensuring safety. Understanding the key elements is crucial for maintaining compliance with regulations and optimizing operational efficiency.

Girard Vapor Recovery Adapter (GVRA)

The Girard Vapor Recovery Adapter (GVRA) plays a central role in vapor recovery systems. It consists of a hydraulically actuated valve installed on top of a DOT407 tank trailer. The GVRA connects the internal vapor space of the tank to a vapor return hose during the loading and unloading process. Designed according to industry-recognized TTMA RP No. 102-21 standards, Girard’s GVRA is one of the most reliable and widely used adapters, ensuring maximum efficiency and ease of operation.

Vapor Line

The vapor line is the internal piping system that creates a path for vapors during transfer. It connects the tank’s vapor space to the vapor recovery adapter. It also often includes integrated check valves or pressure/vacuum relief devices to ensure operational integrity.

Pressure/Vacuum Relief Vents (P/V Vents)

P/V vents aren’t directly involved in vapor recovery but are critical for maintaining safe pressure levels within the tank. These vents prevent the tank from being overpressurized during vapor transfer. They also protect the tank by allowing it to draw in atmospheric air when necessary.

Magnetic Vacuum Breaker

The magnetic vacuum breaker ensures that a vacuum does not build up within the tank when liquid or vapor is being withdrawn faster than it can be replaced. Girard’s DOT407 magnetic vacuum breaker activates only under specific vacuum conditions to maintain optimal tank pressure.

Pressure Gauge

Pressure gauges monitor the internal tank pressure during the recovery process. Proper pressure management is essential for safe operation, efficient recovery, and preventing vapor leakage.

Benefits of Vapor Recovery Systems

Vapor recovery systems on DOT407 tank trailers provide significant advancements in both safety and efficiency. These systems are designed to minimize vapor loss during liquid transfer, ensuring compliance with environmental standards while reducing product waste. By maintaining precise pressure control, vapor recovery systems help protect the integrity of the tank and promote sustainable operations.

Environmental Benefits

Vapor recovery systems minimize the release of harmful chemicals into the atmosphere, reducing air pollution and improving air quality. Systems support adherence to environmental standards, helping operators stay within the limits set by organizations like the Environmental Protection Agency (EPA).

Economic Advantages

Capturing reusable vapors prevents unnecessary wastage of valuable products. Reduced product loss and regulatory fines save money in the long run.

Safety Enhancements

The system reduces the risk of tank over-pressurization and implosions. By controlling vapor accumulation, these systems reduce the chances of ignition and explosion.

Regulations and Compliance

Operating within regulatory guidelines is non-negotiable for DOT407 tank trailer operators. Vapor recovery systems must comply with standards established by federal, state, and local authorities.

Notable Standards and Guidelines

- EPA guidelines: Set limits on emissions and outline vapor recovery requirements for the chemical transportation industry.

- TTMA RP No. 102-21: Details best practices and standards for vapor recovery system components such as the Girard GVRA.

Tips for Ensuring Compliance

- Routine inspections: Perform regular checks on vapor recovery equipment to ensure it functions as intended.

- Training: Equip your team with proper training on vapor recovery operations, focusing on compliance and troubleshooting.

- Documentation: Maintain accurate records of inspections and maintenance to demonstrate adherence to industrial standards.

Maintenance and Best Practices

Proper maintenance and adherence to best practices are essential for ensuring the efficiency and compliance of vapor recovery systems on DOT407 tank trailers. Regular upkeep not only extends the lifespan of equipment but also minimizes the risk of environmental violations and costly repairs. We’ll outline key strategies to maintain system performance and uphold industry standards.

Regular Inspection and Maintenance

The following guidelines are designed to ensure the longevity and reliability of your vapor recovery system. By following these recommendations, you can maintain optimal performance and extend the system’s lifespan.

- Frequent checks: Inspect vapor lines, adapters, and relief vents for wear or damage.

- Calibration: Make sure that pressure gauges and vacuum breakers are accurately calibrated.

- Cleaning: Keep components free of residue and ensure unobstructed vapor flow.

Safe Operations

Closed-loop loading and unloading are essential methods for preventing vapor emissions during product transfer. This involves connecting both discharge and vapor lines between the tank trailer and the facility’s pump or vapor handling system, enabling a completely sealed operation.

Troubleshooting Tips

- Monitor pressure levels: Sudden spikes or drops in pressure may indicate leaks or damaged components.

- Test relief vents: Verify that vents activate at the appropriate pressure levels to prevent equipment failure.

- Inspect adapters: Ensure that all adapters connect securely and do not allow vapor to escape.

The Role of Girard Equipment in Vapor Recovery

Girard Equipment is a trusted name in the hazardous liquid handling industry. Our proprietary DOT407 vapor recovery systems, including the GVRA and specialized components like vacuum breakers and pressure-relief vents, are designed to meet the highest performance and safety standards.

Investing in high-quality equipment from Girard helps operators ensure compliance, safety, and operational efficiency. Check out our vapor recovery systems on tankers today.

Optimize Performance with Vapor Recovery Systems

Effective vapor recovery systems are essential for maintaining safe, efficient, and environmentally responsible operations in the transportation of chemicals. Understanding vapor recovery on DOT407 tanker trailers allows operators to safeguard their operations while meeting stringent regulatory standards.

For industry-leading solutions, explore Girard Equipment’s range of DOT407 vapor recovery systems. Reliability, innovation, and unmatched performance are guaranteed.